Do you have a component that’s impossible to find, expensive to replace, or no longer manufactured? At 2Scale Replicas, we specialize in creating custom 3D assets, ensuring you get exactly the part you need. If you require a specific component reverse-engineered to perfection, our expert team is ready to help.

Why Consider Custom 3D Assets?

Finding specific automotive components—particularly rare, vintage, or highly specialized ones—can be challenging. Often, enthusiasts struggle with sourcing or replicating unique parts. With custom 3D assets, these challenges vanish, replaced by precision, flexibility, and accessibility.

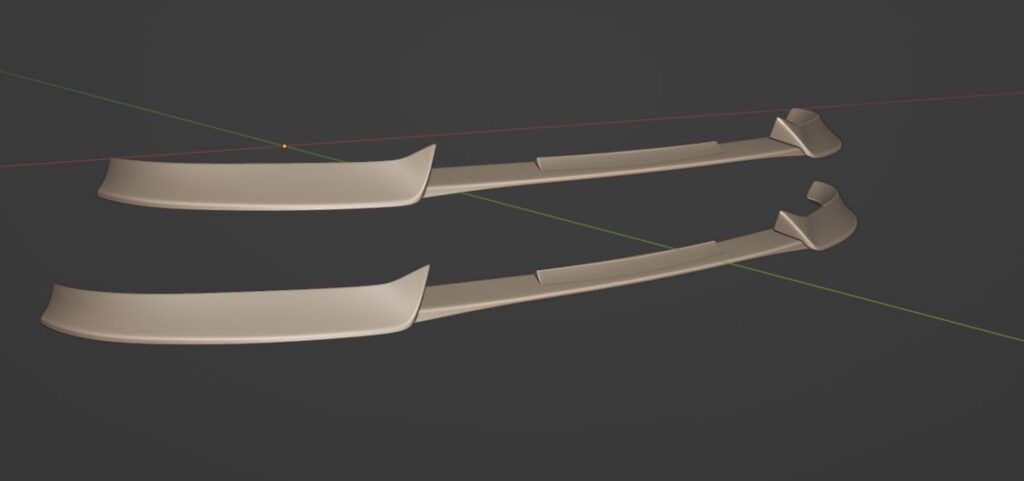

Whether it’s a detailed racing seat, an aerodynamic splitter, or intricate interior trims, custom 3D modeling ensures exact specifications and reliable results.

Reverse Engineering Made Easy

Reverse engineering sounds complex, but the concept is straightforward: we digitally reconstruct existing parts to create exact 3D replicas. Using advanced scanning and modeling software, we transform physical components into precise, detailed digital assets.

Have a damaged racing seat or a unique front splitter that you need replicated? We recreate components digitally, ensuring accuracy in every dimension.

From Real-World to Digital: Our Approach

From Real-World to Digital: Our Approach

The process begins with scanning your component, accurately capturing every angle, dimension, and detail. Then our skilled 3D artists meticulously refine these scans into digital assets using advanced CAD and modeling software. The result is a flawless, ready-to-print 3D asset tailored exactly to your specifications.

Every custom 3D asset undergoes a detailed review, guaranteeing precision and accuracy before delivery.

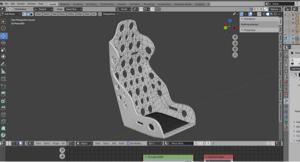

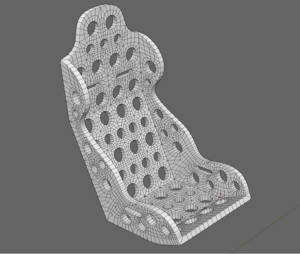

Custom Modeled Racing Seat for a Fabricated Car

The image shown here is a custom racing seat that was specifically modeled for the interior of a fabricated car. Designed with lightweight durability and ergonomic support in mind, the seat features strategic perforations for weight reduction while maintaining structural integrity. Using advanced 3D modeling techniques, every curve and cutout was precisely recreated to ensure a perfect fit for the custom build. This is a prime example of how reverse engineering and digital fabrication can bring unique automotive components to life, offering fully customized solutions for enthusiasts and builders.

Endless Possibilities with Custom 3D Assets

Custom 3D modeling isn’t limited to automotive parts; possibilities extend to industrial prototypes, vintage restoration projects, and even everyday items. Whatever component you have in mind, our custom 3D assets deliver unmatched precision and quality.

Whether you’re restoring a classic vehicle or creating a unique custom build, our reverse-engineering solutions provide reliable, repeatable results.

Need a Component Reverse Engineered?

At 2Scale Replicas, your vision drives our craftsmanship. If you’re looking for accurate, dependable, and meticulously crafted custom 3D assets, reach out today. Our team is ready to bring your idea to reality.